Handling &

Installation

Essential guidelines to ensure a smooth and successful installation

TrimLogic’s PVC-based trim is not only lightweight and durable but also offers superior paint adhesion and ease of installation with standard woodworking tools. Get to know our installation guidelines, because when you install TrimLogic right, you minimize callbacks and complaints from on-going trim maintenance.

Lightweight & flexible

From unloading the truck to moving at the worksite, TrimLogic's manageable weight saves time and trips. Spend more time working, not carrying.

No special tools

TrimLogic can be seamlessly integrated into your projects using normal woodworking tools. Remember to use fine-toothed, carbide-finished trim blades and avoid metal cutting blades for best results.

Fasten without splitting

Splinter-prone wood and engineered wood lead to wasted boards. Dense TrimLogic boards aren’t likely to split even when nailing near ends.

Step-by-Step Installation Guide

Read installation guide before installing

Before your first TrimLogic installation, we recommend thoroughly reviewing the full installation guide. PVC installation is straightforward yet distinct from other materials, and using guidelines meant for other products can result in failures.

Guía de instalación paso a paso

Installation overview

The fastening pattern and adhesive application for TrimLogic are specifically engineered to prevent excessive movement, distinguishing them from wood and fiber cement installations. Adhering to the proper installation guidelines, rather than defaulting to methods used for other materials, ensures long -term stability and mitigates potential issues

Expansion and contraction

Wood expands due to moisture absorption. Paint and sealing cut ends are the primary defense against this, but this requires constant upkeep and eventually water still finds a way. TrimLogic's PVC trim absorbs no moisture. It will experience limited movement across its length with temperature fluctuations, but with the proper fastening & adhesive technique you prevent excessive movement that can lead to failures.

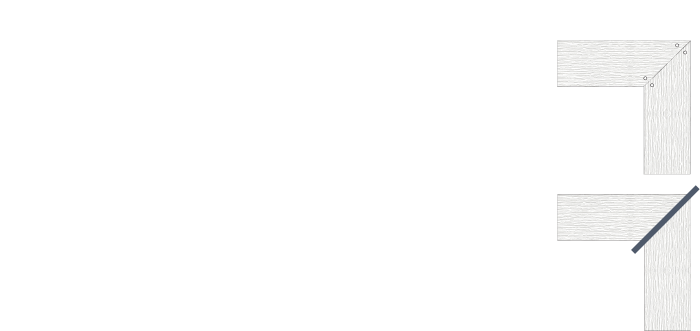

Fastening

For secure installation, fasten TrimLogic within 2 inches of edges. Unlike wood or engineered wood, Trimlogic will not crack or split when fastened near edge. In fact, fastening near edge and minimum 16” on center is required to keep TrimLogic.

Gluing

For joint stability, glue all trim-to-trim joints using AZEK Cellular PVC Cement. Ensure a compression fit for strong bonding. Use scarf joints with two fasteners per side for the best results, avoiding nailing directly through joints.

Temperature considerations and paint color choice

Choosing the right paint type and color will ensure a truly low maintenance, long-lasting painted finish. By adhering to these guidelines, you can ensure your TrimLogic installation remains beautiful and stable, regardless of environmental changes.

Tips for tools, storage & handling

Storage & Handling

To maintain the integrity of TrimLogic materials, store them on a flat, level surface and protect them from direct sunlight and high temperatures before installation. Keep the protective covering on until you're ready to use the product.

Cutting

Use tools designed for wood to cut TrimLogic. Ensure proper support to avoid rough edges.

Drilling

Similar to hardwood, ensure to manage frictional heat and periodically clear shavings.

Routing

Standard router bits are effective, with carbide-tipped bits recommended for optimal performance.

Warnings and special instructions

- TrimLogic is not suitable for structural or load-bearing applications.

- Do not install like wood or fiber cement; adhere to specific TrimLogic guidelines.

- Be cautious of dark colors as they may increase heat absorption, affecting performance.

- For further assistance or inquiries, feel free to contact our Customer Service team at 888-219-8746. Trust TrimLogic for a reliable, long-lasting trim solution that enhances both the beauty and durability of your project.